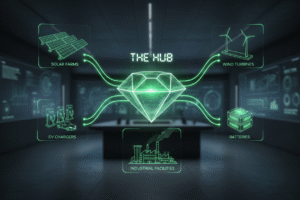

HOMERUN RESOURCES INC. EXECUTES NREL ENDURING THERMAL ENERGY STORAGE GLOBAL INTELLECTUAL PROPERTY AGREEMENT INCLUDING NEW PATENT APPLICATION AND EMS INTEGRATION

KEY POINTS Reno, NV, USA: Homerun Energy USA, Inc. (“Homerun” or the “Company”) a newly formed 100% owned subsidiary of Homerun Resources, Inc. (TSXV: HMR) (OTCQB: HMRFF) is pleased to announce that the Company has signed an Intellectual Property Agreement