- +1 604-862-4184 (WhatsApp)

- [email protected]

- TSXV: HMR | OTC: HMRFF | FSE: 5ZE

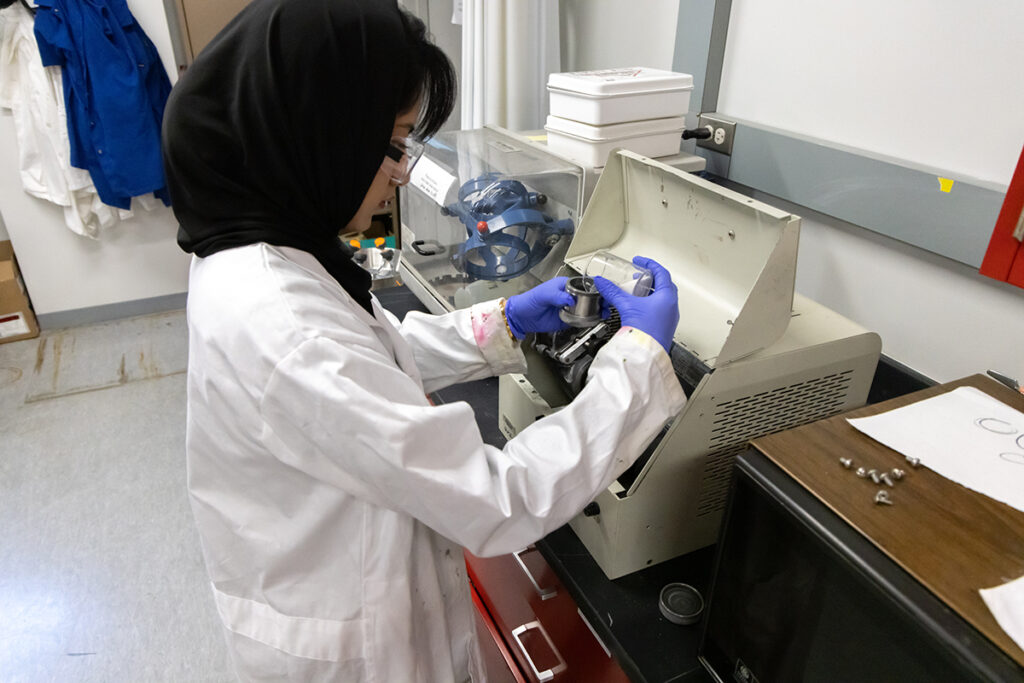

In collaboration with Homerun, researchers at UC Davis have developed a femtosecond thermal laser processing method to purify raw silica sand to a level of 99.999% purity. The single step thermal method uses a femtosecond laser that involves subtle structural and optical phenomena controlled by multiple process parameters. Skillful variation of these conditions produces various topographical features (such as cones and ripples) and microstructural changes (including recombination, oxidation, and amorphization) which depend on specific laser parameters like number and intensity of pulses. The prospect of further adaptation and development of the treatment variables is a vast area of research and major proprietary product development theme.

Subhash H. Risbud, Distinguished Professor, Department of Materials Science and Engineering at the University of California, Davis, stated, “These very exciting results from the current research work with Homerun, have revealed for the first time how a single step laser process can convert raw impure sand samples in as little as two hours to a silica purity level of 99.999%. The thermal laser process used not only avoids the use of hazardous chemicals but also eliminates the need for energy-intensive machinery typically used in mechanical and chemical purification. This laser process is notable for its versatility as the production demands of new semiconductor chip substrates transition from conventional silicon to SiC and other wider bandgap materials. The foundation for these technologies-on-the-horizon are economically produced powders of ultra-pure silica convertible to Silicon, Silicon carbide, Si-nitride and Oxynitrides and Oxycarbides. The broad range of applications of these new materials will make a dramatic impact on the business world of products based on electronic and photonic chips, battery anodes, solar cells, glass and high temperature refractories for steel and metal alloys.”

Thank you to author Mark Crawford at ASME (The America Society of Mechanical Engineers) for the detailed article explaining the success the UC-Davis team has had purifying our Belmonte silica sand. Read the full article HERE

“Purifying the silica was the first step,” Naim said. “The end goal of this project is developing a value chain at the intersection of the battery and the mining industry to help the clean energy transition in the U.S. This will be an advantage to the silicon industry, to the battery industry and to silicon metallurgy. It’s a holistic project.”

Leeners believes the team can develop a fully green purification process for silica sand that will not require chemical treatments.

The team has goals to convert the purified silica into silicon carbide and then advance it to a high enough grade to use in anodes for lithium-ion batteries. Naim has spent the summer months at Lawrence Berkeley National Laboratory working on how to best go about the conversion to silicon carbide.

“Purifying the silica was stage one,” Naim said. “The end goal of this project is developing a value chain at the intersection of the battery and the mining industry to help in the clean energy transition in the U.S. This will be an advantage to the silicon industry, to the battery industry and to silicon metallurgy. It’s a holistic project.”

Using clean energy to purify raw silica and generate battery-grade silicon carbide was one of the reasons lasers were considered in the first place, as opposed to the typical techniques.

“The idea is you take sand, which has impurities in it,” Risbud said. “You heat it, and the impurities leave by evaporation. The normal way of doing this is chemical, which means you put some acid on it, leach it, wash it or do any number of steps in mineralogy and materials science.”

The dream, said Leeners, is to develop a fully green processing technique so those chemicals — which are relatively safe and self-contained in the purifying process — aren’t even part of the equation.

“Theoretically you could have a solar energy generation facility creating the electricity that goes into the thermal processing done by lasers, which would then create silica that is recycled into creating more solar energy through silicon-based photovoltaics,” he said. “It has the potential to be an elegant industrial cycle.”

Source: https://engineering.ucdavis.edu