- +1 604-862-4184 (WhatsApp)

- [email protected]

- TSXV: HMR | OTC: HMRFF | FSE: 5ZE

HPQ silica is an essential component in the manufacturing of semiconductors and silicon wafers used in electronics. Its high purity ensures minimal impurities that could affect the performance of electronic devices.

The optical industry relies on HPQ silica for producing high-quality lenses, prisms, and other optical components. Its clarity, transparency, and thermal stability make it an ideal material for precision optical instruments.

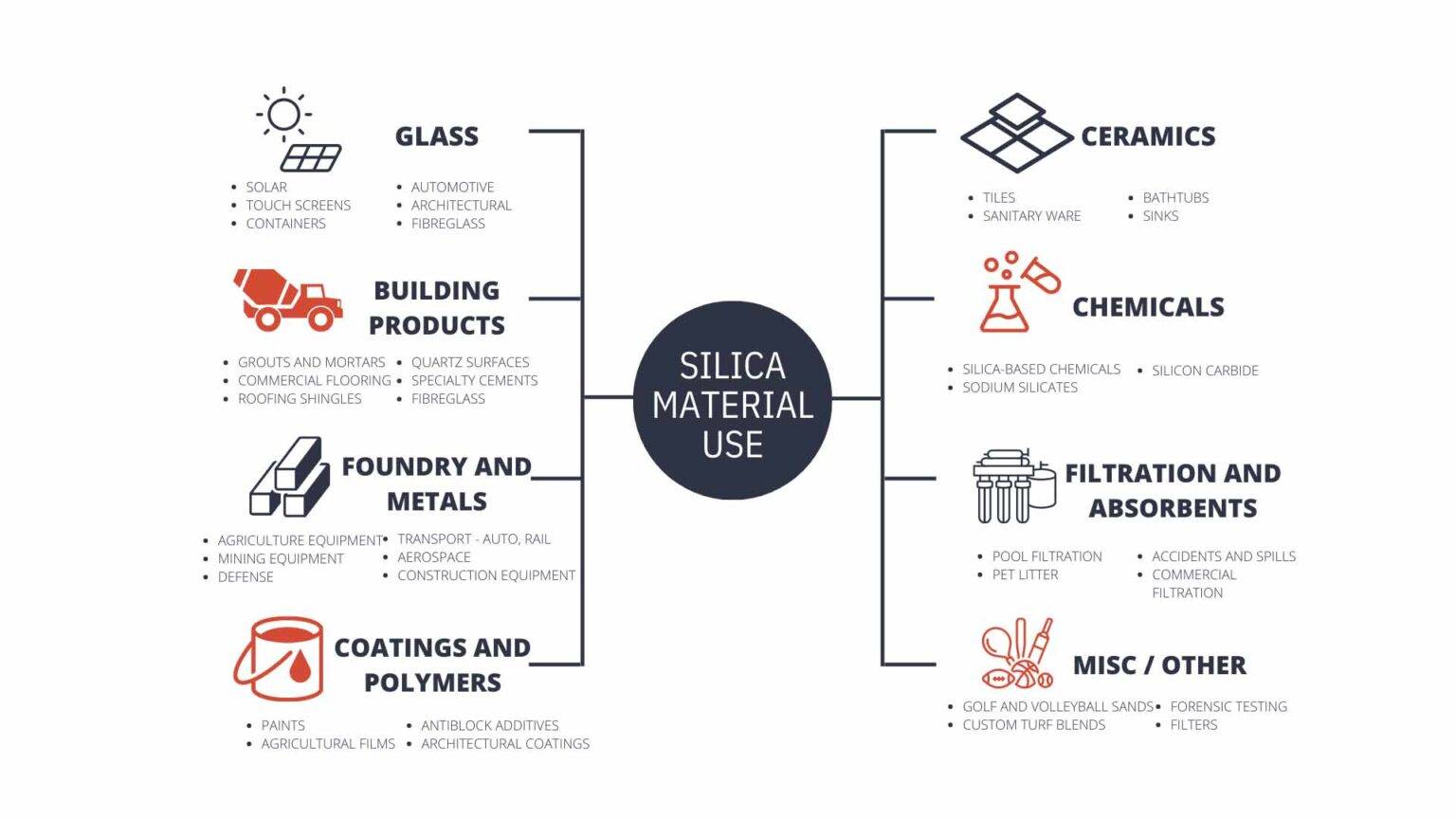

HPQ silica is utilized in the production of ceramics and refractory materials due to its high temperature resistance and low thermal expansion. It’s often used in kiln furniture, crucibles, and insulating materials.

HPQ silica can be used to create thin films and coatings with specific properties, such as anti-reflective coatings for optical lenses, solar panels, and displays.

Silica fume, a byproduct of silicon metal production, is used as an additive in cement to improve its strength and durability. It reduces the permeability of concrete, making it more resistant to water and chemical penetration.

Silica nanoparticles are used in coatings and paints to improve their scratch resistance, UV protection, and moisture resistance. They can also provide a smooth finish and increase the longevity of painted surfaces.

Silica fillers are added to adhesives and sealants to improve their stability, adhesion, and resistance to environmental factors. They also enhance the thixotropic properties of these products.

Silica additives can enhance the properties of flooring materials, such as tiles and epoxy-based coatings. They contribute to abrasion resistance, surface hardness, and adhesion strength.